Introduction

The program minimizes repeat work, improves customer satisfaction, enhances reliability, optimizes efficiency, and helps sustain a strong reputation within the solar industry.

1. Safety & Respect

2. Quality Products & Services

3. Efficiency

4. Organization & Accountability

5. Adopt New Technologies

Our Quality Control Begins With Values

Sustineo’s core values provide the foundation to our quality control and quality assurance program. This foundation fosters our ability to implement high effective practices. The pursuit of our values create a culture of analyzing data, identifying problems, and making informed decisions to improve upon what we deliver to our clients.

Key Elements

The three main elements of Sustineo’s quality control program are due diligence & strategic planning, client coordination & regular updates through software, and 3rd party performance verification.

Due Diligence & Planning

Defining quality standards, setting quality goals, and creating a quality management plan.

Client Coordination & Reviews

Implementing processes and procedures to prevent defects and ensure adherence to quality standards.

Inspections, Testing & 3rd Party Acceptance Verification

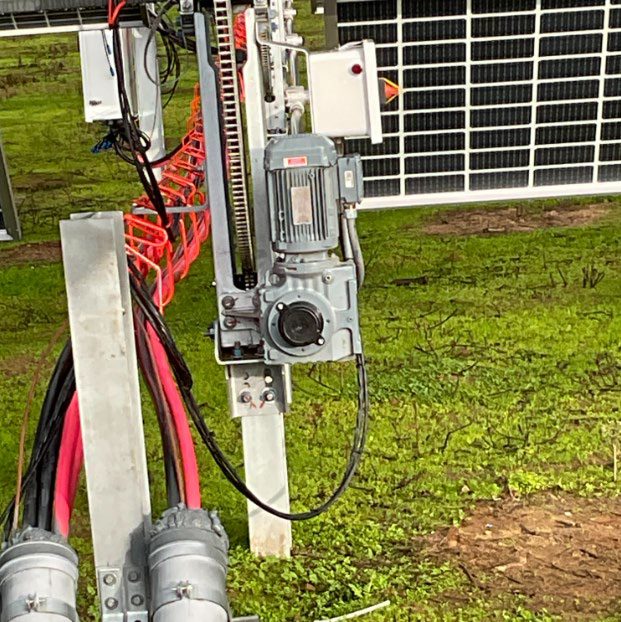

Executing inspections, testing, and measurements to identify the installation of solar assets.

Process Control Through Software

Standardized Processes & Repeatability

Independent Checks & Inspections

3rd Party Verification & Acceptance

Quality Control Methods

These methods and processes are the core of our Quality Control Program. They are incorporated into the 12 stages of our program.

Program Overview

These process provide Sustineo with an organized, repeatable, and proven processes for delivering high quality solar assets to our clients:

1. Due Diligence

(Elec, Struct, Roof, IX)

2. Engineering & Permitting

(30, 60, 90%)

3. Procurement

Planning

4. Safety, Staging, Software

& Records

5. Project Kick-Off

Plan

6. Mobilization

& Setup

7. Construction

& Oversight

8. Inspections

& Reviews

9. Commissioning &

Testing Plan

10. Acceptance & Verification

with Client

11. Demobilization

12. Project Closeout

Plan

Quality Control Methods

Statistical Process Control (SPC)

PC involves using statistical techniques to monitor and verify production of our solar assets. It focuses on collecting and analyzing real-time data to detect under performance early in the solar asset’s operational life. Capacity testing, statistical analysis and R-charts, are commonly used in SPC to visualize performance data and identify patterns or abnormalities even if an asset is installed correctly.

Scope & Specifications Defined

Working closely with our clients to define scope, exclusions, and clarifications helps set projects up for success for on-time delivery

Client Collaboration & Coordination

Using multiple software platforms and providing full transparency into project documentation allows all stakeholders to see current project status at any time.

Inspections to Verify Scope & Quality Assurance

Inspections occur throughout the project using separate internal teams to confirm quality control. All inspections are recorded in our software for review.

3rd Party Capacity Testing & Verification

We utilize a 3rd party to verify project performance once quality control is complete. This process allows for another set of eyes to confirm success.

Quality Control Methods

Total Quality Management (TQM)

TQM integrates quality control across the organization, involving all employees in improvement initiatives and fostering a culture of continuous learning. It emphasizes customer satisfaction, process improvement, and the use of quality tools to enhance organizational performance.

Focus On Customer

Continual Improvement Training & Apprenticeship

Communication

Decision-Making Based On Facts

Employee Involvement

Process Centered

Integrated System

Strategic and Systematic Approach

Quality Control Tools

Quality Control Tools

Checklists ensure step and criteria compliance. Standardize processes, reduce errors and improve consistency. The software and their corresponding uses are used in each of the quality control states for effective optimization. Adopting new software technologies, helps Sustineo scale and provide increased efficiencies both internally and externally to our clients.

| Safety Inspections | Process Control | Drawings & Photos | Time Management | Statistical Analysis | |

| Software & Record Keeping | |||||

| Site Docs | ✔ | ✔ | |||

| Scoop | ✔ | ✔ | |||

| Procore | ✔ | ||||

| Sage 100 Contractor | ✔ | ✔ | |||

| Capacity Testing (3rd Party | ✔ | ||||

| AlsoEnergy + System Model (Tracking) | ✔ | ||||